BLOG 29 - "In the Pacific, Islands Come and Islands Go" - Departure Routines from an ER Perspective

- ranganathanblog

- Apr 13, 2022

- 12 min read

Updated: Aug 8, 2025

Chapter 15 – Departure Routines on Board – What we do on Board when we sail out of a port.

Routine voyages followed after our departure from Kandla.

First it was Goa to load iron ore for Japan. Then a ballast voyage to Port Kembla in Australia to load coal for Japan. A wheat contract saw us go across the Pacific to Vancouver BC to carry grain back to India.

A ROUTINE DEPARTURE FROM PORT – SEQUENCE OF EVENTS / ACTIONS FROM AN ENGINE ROOM PERSPECTIVE

There are several periods of standard operations when a ship is vulnerable to accidents and, hence, requires a sense of heightened alertness and supervision.

Departure and Arrival ports is one such period.

On a ship with efficient staff, a well oiled infrastructure surges into action during these 'vulnerable' periods and smoothly effects the operation without any untoward incident. Good communication and cooperation between various segments of personnel is of prime importance.

The estimated time of departure from a port (ETD) is entirely dependent on the completion of cargo, either loading or discharging or both, depending on what type of ship it is.

Bulk carriers mostly either discharge or load an entire cargo. They sometimes load different grades of the same cargo – for example, different grades of coal – for discharge in different ports, the receivers also could be different companies.

On completion of cargo, a draft survey is undertaken in order to determine the tonnage of cargo loaded or discharged. This constitutes the 'bread and butter' of the Company, Owner and Ship.

A pilot is booked for a particular time, to pilot the ship out of the harbour. The port provides line handlers at the proper time to ‘let go’ the ropes from the ‘bollards’ to which the ship has been tied.

Tugs are ordered to standby from a particular time onwards. As tugs' hourly rates are high and constitute a major portion of vessel’s or charterer’s port expenses, estimation of departure time becomes valuable. Depending on the port and the country, tugs have to be given advance notice of 2 or 4 or 6 hours.

Meanwhile, on a well run ship where people have good communications, all maintenance work in the Engine Room is planned for completion at least 2 hours prior ETD. There have been several occasions where ‘must do’ jobs are completed only at the last minute. Delays to keeping the Main Engine ready can be costly to an Owner. This is sometimes avoided by a sleight of hand, by asking the cooperative Port Supervisor to reduce loading rates in order to delay the departure of the ship. There are also other ways to do so, a case of beer usually being sufficient.

In earlier years and on ships that were entirely manually operated, a 2 hour notice would be given to the Engine Room to keep engines ready. A series of events then take place.

Termed "Starting the Plant", meant 'warming up' the engine, starting the Lubricating Oil Purifier, starting the Lubricating Oil pump, starting another generator, pressing up the compressed air bottles, starting the Diesel Oil Purifier to fill the Diesel Oil Service Tank (because the Main Engine would have been changed over from Fuel Oil to Diesel Oil before coming into port), heating up the Fuel Oil Service and Settling tanks for use on short notice, starting up the Fuel Oil Purifier, and generally, keeping all systems ready.

In later years, on more modern ships, most of these jobs were taken care of by automation, with only checks to be performed that all systems were ready. Mandatory check lists needed to be gone through and filed for later audits.

In the 1970s and the first part of the 1980s, there were no mandatory check lists – you made your own.

Next step – cargo is completed, hatches are closed and battened down, Draft and cargo survey is completed, documents are signed, agent gets necessary documents signed by the Captain, ship’s documents and cargo papers are handed over to the Captain, 'Port Clearance' is obtained from the Harbour Master and handed over to the Master, all shore based personnel leave the ship.

2 hours of hectic activity involving a host of people is successfully gone through. This also includes ship chandlers who have supplied provisions to the vessel and bunkers supplied. In later years, this list will include spares brought over by agent’s staff and workshop’s completing work in the Engine Room or deck. All shore based personnel are off the ship. The heightened activity is now at it’s peak and will remain so for at least the next two hours or more.

The Pilot boards the vessel and is escorted to the Bridge. The gangway is raised and secured. The Engine Telegraph is tried out. The steering gear is started and checked, The rudder is tried out. The Main Engine is ‘blown thro’ on air, started and tried out on fuel in ‘Ahead’ and ‘Astern’ directions, with engine staff specifically checking areas where work has been carried out. The Duty Engineer informs the Bridge that Engines are ready.

On the automated ships of later years, the ‘blowing thro’ is done from the Engine Room and the trial starts are done after controls are transferred to the Bridge.

Technically, this trying out of engines could have been scheduled for an earlier time, but may involve the stopping of cargo operations, because of the likelihood of the ship moving ahead or astern, while being held in place by ropes only. When major maintenance jobs are carried out on the Main Engine, it is prudent to try out the Main Engine to rectify any leaks, at which time extra ropes are used to secure the ship.

The tugs and line handlers are in readiness. The order comes from the Bridge to the Forward and Aft Stations – ‘Single Up’.

A typical mooring scheme

Number Name Purpose

1 Head line Keeps forward part of the ship against the dock

2 Forward Breast Line Keeps ship close to pier

3 Forward or Head Spring Prevents forward movement

4 Back or Aft Spring Prevents back movement

5 Aft Breast line Keeps ship close to pier

6 Stern line Prevent forwards movement

For an average sized ship, like the Chennai Perumai, about 8 ropes were used to moor the ship to a pier, with more put out in anticipation of rough weather. Bigger ships, longer ships, heavier ships would have more number of ropes put out, sometimes as many as 18.

During port stays, a careful and continuous watch is kept on all these ropes and are tightened or slackened with changes in draft of the ship, rise or fall in tide, heightened winds or swell.

A ‘Single Up’ command would mean to ‘let go’ all ropes except one in Forward Stations and ‘let go’ all ropes except one in Aft Stations. Usually, Chief Officer would be in charge of Forward Stations, Second Officer in charge of Aft Stations, with Captain on the Bridge in overall command, with the Third Officer operating the Telegraph as per orders and relaying Helm orders to the Helmsman. The Bridge becomes a beehive of activity, where two to three hours ago it would have been desolate, with only the occasional squawk from the VHF disturbing the peace.

When the tugs are ready to pull the ship, the last two lines are let go. The ship slowly gets pulled out parallel to the pier into the channel. Then the order is given via Engine Telegraph – “Dead Slow’ or ‘Slow’ Ahead or Astern as required.

Sometimes the vessel may be facing the wrong way around and may need to turn around 180 degrees in order to face the mouth of the harbour. For this, several engine movements can be expected, along with the tugs assisting by either pulling or pushing the ship. Sometimes the turning radius is just enough and all personnel on the Bridge, Fore and Aft spend some tense minutes while the ship is rotating. The possibility exists of either grounding or hitting another ship that is moored close by. Contingency plans in such cases include using the tugs to stop the turn, drop anchors to stop the momentum or use engines. The longer or bigger the ship, more is the tension.

So, we make for the harbour entrance and into the channel and, using the (coloured red or green) buoys which are anchored at specific points as navigational guides, leave the port behind and, navigating through the marked channel, drop the pilot. Depending on the width of the deepened channel, ships keep to the starboard side, akin to driving on the right side of the road.

Shortly thereafter, “Full Away” is given, which means we have to go to full sea speed as soon as possible. On the older ships the rpm was increased manually and slowly, keeping an eye on all engine parameters. In later ships this is done automatically, called a ‘Load Up Program’, with the Chief Engineer setting the higher limits of either fuel consumption or load on the engine or rpm.

It must be remembered here that, unlike later ships, these ship’s engines (MAN KZ Type) were totally manual. There was no automation and very little pneumatics or hydraulics in responding to a Telegraph order. One replied to the Telegraph order by repeating the order on the Telegraph itself and coinciding both pointers. That is the first action.

Engine Telegraph - Old Style

Engine Telegraph - Modern

It is followed by shifting a lever to an “Ahead” or an “Astern” position, which action, in turn, will shift the Main Engine camshaft in a longitudinal direction to bring the appropriate “Ahead” or “Astern” fuel cam under the respective fuel pump. The next action is to start rotating the “Starting Wheel”, bring it to the “Start” position, listen to the engine being supplied with compressed starting air, see the engine start to rotate on the tachometer and also watch the camshaft rotate, turn the Starting Wheel anticlockwise to ‘fuel’ position, which action cuts off the starting air and introduces fuel into the engine for combustion. The Starting Wheel is then rotated either way to give more or less fuel, in order to gain and maintain the rpm needed as per the Telegraph order.

All these actions seem time consuming and complicated but, in actual fact, is completed in less than 20 seconds by a trained hand. Stopping the engine is done by rotating the starting wheel clockwise to its ‘Stop’ position.

In modern ships, all the above happens automatically on giving the order on the Telegraph, when on 'Bridge Control'. Hydraulics, pneumatics and a host of sensors do all the work that was done manually. With all these added frills, it is possible to accidentally start the engine, were the telegraph handle to be moved accidentally - with extreme danger to life, limb and vessel. This can happen if shut down procedures are not followed correctly.

Whether modern or old, most ship's engines are designed to run at an rpm around 110 ~ 120 when at full speed at sea. Manoeuvring speeds (rpms) are much lower, when the ship is entering or departing a port, with rpms varying from around 30 on 'Dead Slow' and around 70 on 'Full'.

Some of the latest of ships are designed to for 'slow steaming', running at around 30 to 40 rpm and consuming as little as 9 MT/day of fuel.

Chapter 16 – An Amusing Incident of Islands in the Pacific

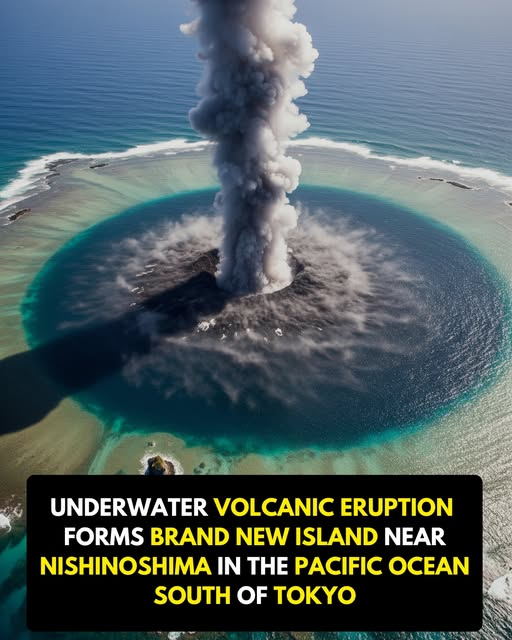

PROOF OF ‘IN THE PACIFIC, ISLANDS MAY COME AND ISLANDS MAY GO’

We were crossing the Pacific, eastbound, headed for one of the US West Coast ports or Vancouver in Canada. The weather was remarkably mild. The sea was like glass, placid and pacific. The days were routinely monotonous. I was keeping the 8~12 watch. We were doing a sedate 12 knots at about 112 rpm.

One Sunday morning, around 0930Hrs, the sound powered phone rang. It was the Third Mate, who was keeping watch on the Bridge. He sounded very agitated and unclear. He said something that sounded like ‘Stop, Stop’. At the same time the Engine Telegraph sounded, with the order “STOP’ and a double ring "Full Astern', the double ring denoting an emergency. We were then at sea speed, with the order on the telegraph set at “Full Away”.

Normally, when intending to stop the engine and the ship, for example when picking up a pilot, or the intention is to reduce speed in advance of getting into high density traffic, the Bridge gives the Engine Room advance notice, which could be a notice of 1 hour or lesser, depending on the circumstance. This is in order to reduce engine temperatures gradually, so that a steep temperature gradient of the involved engine components is not created and heat stresses are avoided. Extra personnel would also be called or woken up, to be of assistance.

But emergencies mean that action has to be prompt, irrespective of what damage a sudden slowing down can cause. The signal on an Engine Telegraph for Emergency speeds, either “Ahead’ or ‘Astern’ is a double ring on the Telegraph, informing the Engineer concerned “Give me maximum possible revolutions”.

Unlike land based transportation systems like cars, trucks or trains, the ship does not have a ‘braking’ system to instantly stop. On cutting off of fuel, the engine does not come to a stop immediately. The momentum of the ship will be such that it may take 10 minutes or longer to stop if the engine had been running on full sea speed. The propeller and engine will be turning and turning all this while. In such cases, there are only 2 methods of slowing the ship more quickly in mid sea. One is to use the rudder hard-a-port and hard-a-starboard repeatedly to slow the momentum of the ship. The second is to put the manoeuvring wheel on ‘astern’ and apply ‘braking air’ to the engine, after the rpm of the engine has reduced to close to 30. This may need to be done several times, before the engine starts going astern. Engine manufacturers do not recommend this, as it causes torsional stress on the moving parts.

Getting back to the emergency orders received from the Bridge on the Engine Telegraph, action was taken by me, ‘braking air’ supplied several times before the engine rotated in the astern direction. This was a Sunday and no day workers had come down. But, hearing the engine slow down quickly – with consequent heavy surging of the three turbochargers – all Engineers and many of the Engine Crew rushed down to see what was happening and to assist. All they saw was the Engine Telegraph on ‘Full Astern’ with the rpm slowly rising in the ‘astern’ direction, while the Duty Motorman was rushing around trying to control temperatures and pressures, while I was monitoring the rpm of the engine and slowly increasing the fuel, while operating the nearby air compressors.

From the time ‘braking air’ was applied to the time the astern rpm reached its maximum, about 12 minutes must have elapsed. I, then, called the Bridge and told the 3rd Mate who came on the line that we have reached the maximum astern rpm possible.

I queried him as to the nature of the emergency. No reply was forthcoming. Instead, the Engine Telegraph sounded with the order to stop. Within 30 seconds the order was “Full Ahead’ immediately followed by ‘Full Away’. The next half an hour went with stabilising fluctuating temperatures and pressures. We were all busy till the end of the watch.

During this chaos, the Chief Mate and Second Mate had also gone to the Bridge to see what was happening. The Third Mate was on duty and he later told me what happened. The conversation went like this:

The Master (Captain) enters the Bridge and looks out. The Master then screams at the Third Mate.

Master: What are you doing Third Mate? What kind of a watch are you keeping?

3rd Mate: (Obviously flustered) Starts stuttering – What, what?

Master: Can’t you see that island right in front of you? Call the Engine Room. Give "Stop ' on the telegraph and Double Ring ‘Full Astern’ on the Engine Telegraph immediately.

The 3rd Mate carries out the order and asks the Captain ‘What island, where?’

Master: Right ahead of us, you idiot. We will run aground if the vessel does not pick up speed in the astern direction.

3rd Mate: (Frantically using binoculars to check for the island) But I don’t see any island, Sir.

Master: What? You can’t see the island right in front of your nose? Give me the bloody binoculars, you moron.

The Captain, agitated, takes the binoculars and searches and slowly calms down when he sees nothing.

The AB, who was on lookout duties, is equally flabbergasted, but keeps quiet.

Master: I am certain there was an island there (and continues searching).

Meanwhile the 3rd Mate attends to my call from the Engine Room.

Master: (After searching and slowly coming to the conclusion that there is nothing but the open waters of the Pacific) Okay, stop engines and give Full Ahead and Full Away.

The 3rd Mate does so quietly, with no fuss.

Master: (After about 5 minutes) You know, Third Mate, in the Pacific, Islands come and Islands go. So we need to be careful and keep a sharp lookout. (And he nonchalantly proceeded back to his cabin).

Only a few people came to know the details of this incident and we kept it that way, so as not to embarrass a good Captain.

But here I have to be absolutely frank. The Captain may have been hasty in his one glance assessment that there was an island ahead. But islands do appear and disappear in the Pacific, due to volcanic, seismic or tectonic plate activity. It has happened before and will happen again. Only thing is, it takes a few weeks or months and may remain uncharted for quite a while.

But there was a more serious fall out of the sudden changes in engine rpm, the repeated injection of cold compressed air into a hot engine (braking air) and the eventual return to normal.

Heat stresses were caused with the metallurgically weakest parts being affected, later causing cracks to appear on running parts. Already a worn engine, this thermal stressing could have been the cause that triggered the subsequent series of events on the return voyage through the North Pacific Ocean.

===== Continued in Blog 30 - Lives in Jeopardy =====

Comments